50% composition of "Running cost of IMM cost" = Processing Time + Free Time

Reduce free time means increasing processing time while profit.

May be you feel nothing with just one set of IMM.

How about 5 sets, 50 sets ,100 sets ,500 sets and even 1000 sets......?

Automatic workshop can reduce IMM's free time significantly. It's also an important premise and guarantee to get ready for Industry 4.0 and 5.0.

However, it's really a problem to achieving one-step completely automatization. Not only huge investment needed, but also hard to succeed.

Therefore, many customers of SML chose piecewise automatic transformation, connect them when they are mature.

Automatic workshop cases sharing

01Robot&Crusher, Convenient for recycle

·Lightweight swing arm: Greatly saves the installation space of IMM.

·Crusher: Convenient to recycling, packaging, transportation and storage.

02Gravimetric dosing and mixing unit

·Apply to multiple raw materials which need accurate weighing and mixing by proportional in plastic cases. It can control precision within ±0.5%.

·Japanese made advanced system module, with the function of automatic calibration, program compensation, alarm recording, fomula storage, etc.

·Moveable frame, material hopper, pneumatic discharge valve, damped rotation type level indicator and suction box are optional.

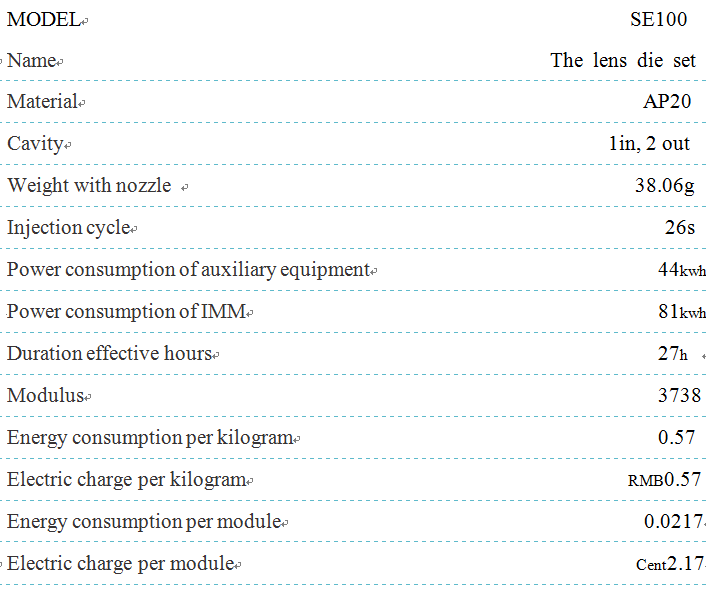

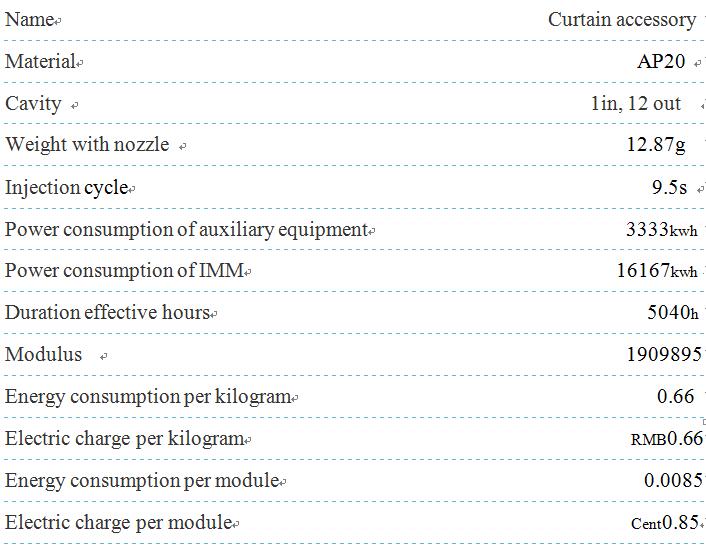

03One-stop shopping, energy saving is measurable

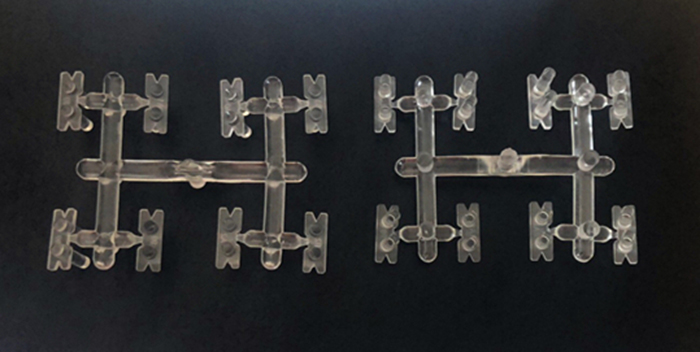

Product case

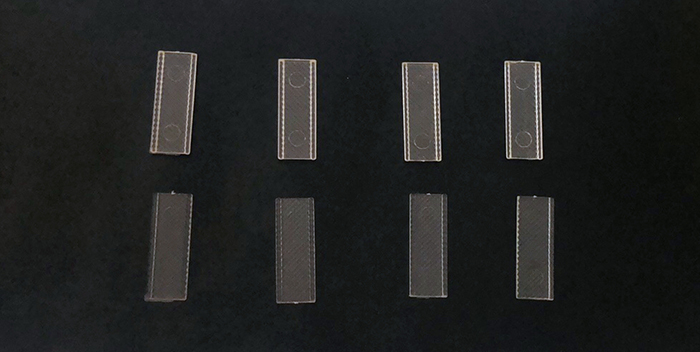

01 Light Pipe

1in,24out

Material:PC

Injection cycle:21s

(4s faster than before)

Cooling:11s

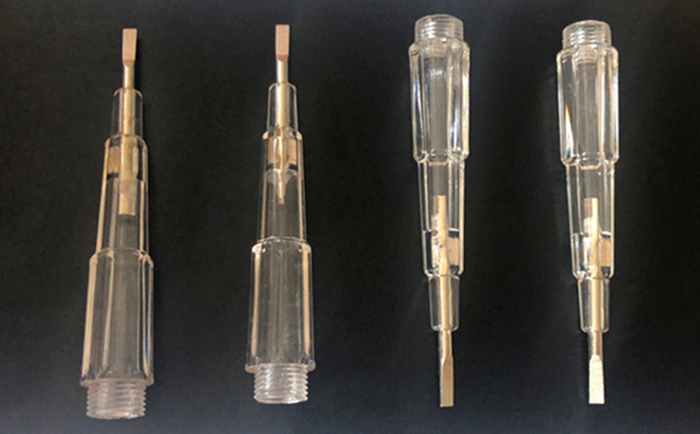

02 Digital display board of Electric pen

1 in, 32 out

Material:AS

Period: 20s

03 Electric pen

1in, 6 out

Material:AS

Period: 30s

Standard robot unit to customized, integrated system solutions, SML meticulously meets the special automation requirements of injection molding enterprises.